Pressure Relief valves

Pressure Relief Valves are used to control pressure in a system. Pressure is relieved by forcing open a valve set to a specific limit which when met or exceeded allows the pressurized fluid to flow from an auxiliary passage out of the system. Once valve's reseating pressure is met the valve will close. Blowdown is quantified as a percentage of set pressures and refers to the reduction in pressure needed before the valve reseats.

Our pressure relief controls can manage pressure as a single purpose valve, or can be paired with a thermal control unit. Our pressure relief valves span from small precise units that are utilized in the aerospace industry all the way to simple freeze protection devices for residential and commerical building projects. The controls featured on this page are set in-house to your secific requirments. We offer several types of pressure relief valves please read below for more details on those specific types.

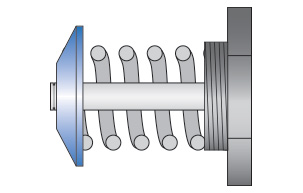

Poppet Pressure ReliefA poppet pressure relief valve is manufactured to be placed within a machined housing where the valve's seat is machined. The manifold contains ports and fittings mandated by your specific system while the poppet pressure relief valve regulates pressure according to your specifications.

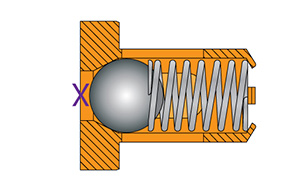

Cartridge Pressure ReliefA cartridge pressure relief valve is special in the way that it contains the valve head and the valve seat. This valve does not require a manifold to function, typically this valve is inserted into an open ended pipe with an elbow where the valve blocks flow unless the pressure setting is exceeded. See diagram below for further clarification.

Custom Pressure Relief

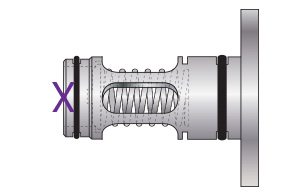

Many customers need special sizes and configurations when dealing with pressure relief applications. We offer complete flexibility when working with our engineers. Some custom features include miniature sizes, low pressure settings, adjustable functions, and thermal bypass. Present an idea to our engineers and they will quickly develop a solution tailored to your needs.

Thermal Valves - Diverting & Mixing (Mouse Over Images To Animate)

Pressure Relief Valve Types & Function

We offer a wide range of valves that all fall under the general category of "Pressure Relief Valve" however each valve has unique functions and features. Please use the list below to better educate yourself on the options you have available to you.

| Generalized Part # | Primary/Secondary Function | Port Diameter | Port # | Materials | Drawing |

| 0250-00-00 | Thermal Bypass / Safety Pressure Relief | 1/4" (6.35mm) | 3 | * Aluminum * Brass * Stainless Steel |

*.DWG |

| 0500-00-00 | Thermal Bypass / Safety Pressure Relief | 1/2" (12.7mm) | 3 | * Aluminum * Brass * Stainless Steel |

*.DWG |

| xxxx-xx-xx | Thermal Bypass / (N/A) | 1/2" (12.7mm) | 2 | * Aluminum * Brass * Stainless Steel |

*.DWG |